History

Pinghu Yipinxiang Machinery Technology co., Ltd. was formerly known as pinghu Dingmao Hardware Factory ,which was established in 2006. The company mainly produces all kinds of hinge fittings, including hinge bearings, bushings, pins and other supporting products, the production process is formed by cold pier equipment extrusion.

In 2016, the Company was established to meet the development needs. Through various ways such as building plants, acquiring equipment and training personnel, we have developed a variety of cold pier forming welded hinges on the basis of maintaining the supply of the original hinge parts. These products can be produced mechanically, with reliable quality, suitable for mass production and have obvious cost advantages. Since the development of the products, they have been widely loved by distributors in many countries.

Manufacturer: Pinghu Yipinxiang Machinery Technology Co., Ltd

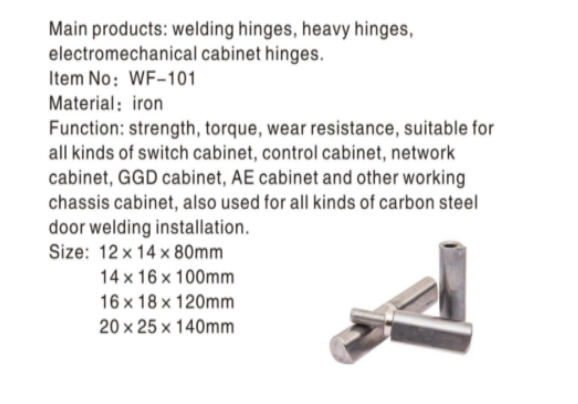

Brand: YPX

Size: ∅ 20X25X140mm

Product model: WF-101

Material: iron

DESCRIPTION:

:strength, torque, wear resistance, suitable for all kinds of switch cabinet, control cabinet, network cabinet, GGD cabinet, AE cabinet and other working chassis cabinet, also used for all kinds of carbon steel door welding installation.

Company name: Pinghu Yipinxiang Machinery Technology Co., Ltd

Company email: summerchu@phypinxing.com

Company phone number: 18767359360

Company address: West Of Ground Floor, No. 118, Qinsha Section, Pinglang Line, Xincang Town, Jiaxing, Zhejiang, CN

Company Profile:

Pinghu Yipinxiang Machinery Technology Co., Ltd. is a specialized company dedicated to the production of welded hinges and hinge accessories. Located in Zhejiang, China, since its establishment in 2006, it has undergone significant growth from a small-scale operation to a standardized factory.

Business scope and advantages:

With 6 advanced multi-station cold pier machines, over 20 sets of production equipment, and 4 sets of automatic packaging equipment, our products boast reliable quality while enhancing production efficiency and reducing labor costs. Our daily output of welding hinges reaches an impressive 10,000 sets, effectively meeting the demands of large-scale customers. Additionally, we have a dedicated R&D team and quality inspection team that provide comprehensive services encompassing design and customized production for our valued clients.